BATTERY COOLING WITH AMAG TOPCLAD®

Political requirements aimed at reducing CO2-emissions from vehicles and the ever-increasing individual interest in e-mobility are helping battery electric vehicles (BEV) and hybrid electric vehicle (PHEV) achieve significant growth by 2030. According to various studies, every third new car registered in Europe in 2030 could be an electric car.

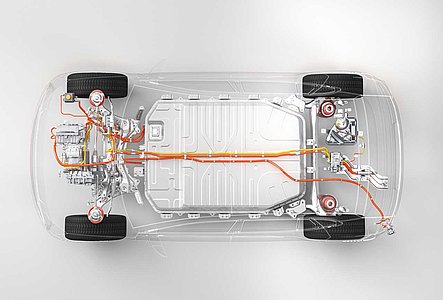

Battery cells are the key component of an electric car. Most importantly, they should be safe, durable and as light as possible. That is why aluminium is a crucial material for electromobility by compensating for the additional hundreds of kilograms weight of the batteries.

In addition to housing trays, underrun protection, battery frames and crash-absorbing battery housings, an aluminium battery cooling system is particularly important for thermal management in the vehicle, in order to increase the performance and service life of the battery.

A lot of heat can be generated in an electric car, especially when accelerating or charging, which must be dissipated from the battery box by means of cooling. The typical cooling plates consist of a thicker base plate (1.5 - 2.0 mm) and a thinner channel plate (0.8 mm - 1.2 mm) made of braze clad or protective plated alloys. Cooling channels on the channel plates are formed and the two plates are then joined in a continuous furnace by CAB-brazing (controlled atmosphere brazing).

Due to design requirements, the cooling plate sometimes also has a stiffening or support function. In this case, a higher-strength material can support the design optimization with the aim of high rigidity. For these applications, AMAG has a wide range of long-life alloys at its disposal.

Customer benefits from AMAG TOPCLAD® for battery cooling:

- All required thicknesses and width ranges

- All application-related material combinations

- Top quality from the most modern rolling mill in Europe

- Support in development and prototype construction

In recent years, AMAG has invested more than one billion euros in its Ranshofen plant. With the new hot and cold rolling mill and a new assembly station, it is now possible to produce brazing sheets up to 2100 mm in width.