Casting

AMAG casting sees itself not only as a reliable supplier of high-quality casting alloys, but also offers its customers technological support and cooperation in development projects. Comprehensive know-how, technological expertise, many years of experience in the field of wrought and cast alloys, combined with the corresponding infrastructure at the Ranshofen site (test foundry, SEM, TEM, EBSD, etc.), enable optimal customer and project support.

AMAG casting is one of Europe's largest aluminium recyclers at a single location.

Core competencies

- Scrap sampling according to the latest standards

- Modern, environmentally friendly melting capacities

- Ingot casting plants for qualities tailored to customers' needs

- Filling stations for liquid aluminium

- High-quality recycling casting alloys specially adapted to customers' needs (AMAG TopCast® products)

- Electromagnetic rolling slab casting plants (EMC)

- Casting know-how for rolling slabs in the alloys 1xxx, 2xxx, 3xxx, 4xxx, 5xxx, 6xxx, 7xxx and 8xxx

⇒ REACH Regulation / CLP Regulation

⇒ Safety data sheets AMAG casting GmbH

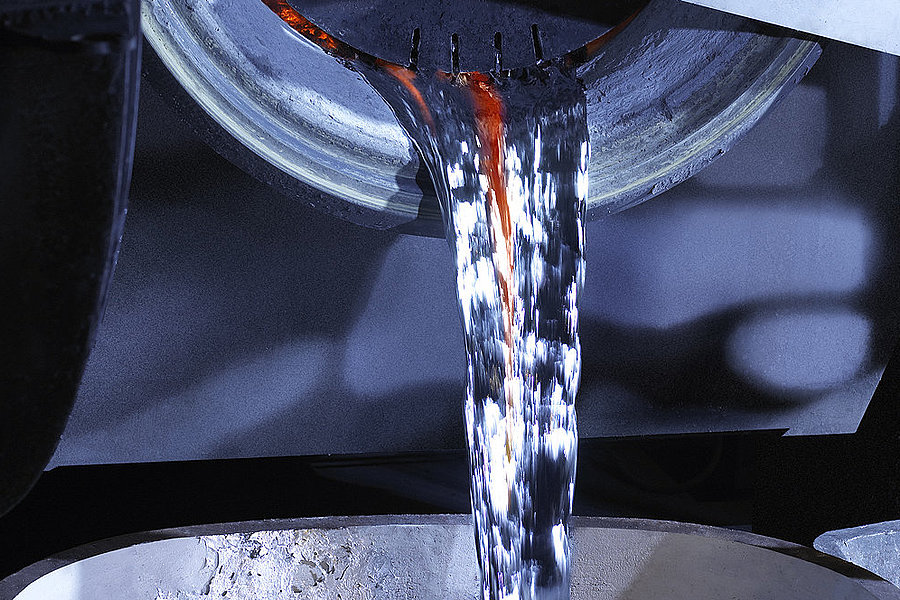

Mobile tipping station - flexible and safe

The mobile, hydraulic tipping station opens up new possibilities for our customers, entirely in terms of productivity increases and cost savings. The tipping station can be transported to the customer at short notice, is flexible and can be installed on site, usually within 2-3 days. Installation and handling are carried out without any problems and they are also supervised and accompanied by an AMAG technologist during the introductory phase.

Advantages of the mobile tipping station

- Transport with standard truck

- Space-saving and standardised block construction

- Maintaining the required temperature for hours or with natural gas burners even for several days

- Use of the liquid aluminium without waiting and preparation times