AEROSPACE

Flying greener thanks to a unique value chain

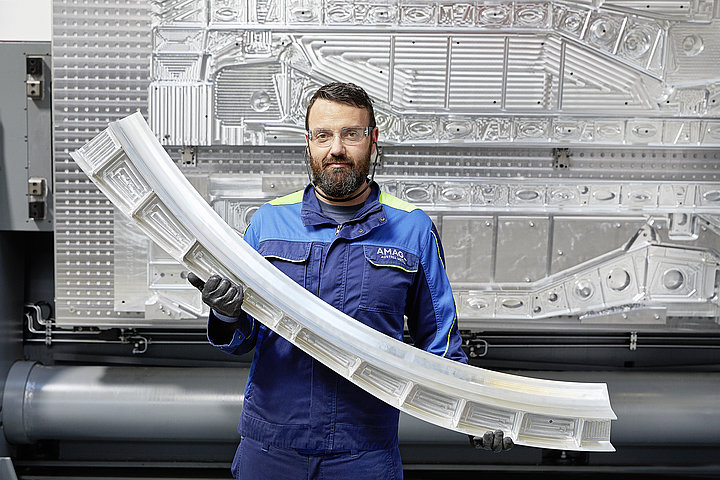

Foundry, rolling mill, mechanical production and high recycling competence - this unique combination of capabilities across the entire value chain enables AMAG Austria Metall AG to optimize the use of materials for aircraft structural components in the best possible way and to close material cycles. The result: products with an improved buy-to-fly ratio at different levels of the value chain that not only reduce costs and complexity, but also conserve resources, reduce transport volumes and lead to significant CO2 savings.

In this industry, AMAG scores with

- reliability and quality

- customer service, customer proximity and flexibility

- sustainability and unique closed-loop recycling

- manufacturing competence of complex structural components

- security of supply through a fully integrated supply chain

- everything from a single source - from the primary material to the ready-to-install component