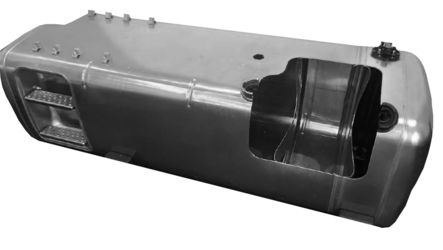

FUEL TANK SHELL PLATES

In an age of globalized production chains, when just-in-time production reduces stocks and warehouses in the manu- facturing industry, goods transport by truck has become an indispensable part of the economy and manufacturing process. But public transport and commuter bus traffic on the roads must also be guaranteed.

The fuel tank for these transport vehicles consists of a shell, baffles, a filler neck, fuel line connectors, vent valves, end caps and mounting brackets. Furthermore auxiliar tanks can be fitted to the tanks. However, the fuel tanks still need to be as large as possible and make the best possible use of the permissible capacity. That is why the tolerance requirements for the width and length or diameter of fuel tanks are particularly restrictive. This is seen in the requirements for the width and length of aluminium sheets used to manufacture the fuel tanks.

For safety reasons and to ensure the strength and stiffness of the fuel tanks, very narrow wall thickness tolerances as well as precisely defined mechanical properties of fuel tank sheets are necessary.

Since fuel tanks are visible on many transport vehicles, it is desirable to have a smooth surface structure without visible scratches as well as a uniform surface finish of the metal sheets used to manufacture the fuel tanks. The surface gloss of the material used must always be reproducible, because fuel tanks are made up of several segments, which must under no circumstances differ in shade.

Customer Benefits:

The complex requirements of this product in terms of surface finish, shape tolerances and mechanical characteristics require an extremely high degree of precision in the manufacture of the sheet metal used for fuel tank production. With regard to these complex requirements and alloy selection, the new AMAG AL4® ABS 5754 sheet for fuel tanks was developed in cooperation with renowned fuel tank manufacturers. It is now available on the market.