RIM INSERTS BASED ON ROLLED ALUMINUM USED IN THE AUTOMOTIVE INDUSTRY.

With a history in manufacturing bright products of close to 40 years, AMAG has become one of the top suppliers for rolled aluminum suitable for applications that require not only a high formability and corrosion resistance, but on top of that an appealing appearance.

THE CARBON OPTIMIZED CAR WHEEL.

A carbon optimized wheel should reduce emissions in both the production and use phases. If rim inserts, ideally made from a sheet with a high proportion of recycled material, are installed on a standard low-pressure die-cast rim based on a primary casting alloy, only the use phase is optimized. This leads to a reduction in fuel consumption of several percent. The rim wheel itself can however also be optimized through the use of AMAG AlSi7.REC, a recycled cast alloy with at least 70% scrap content (see AluRep 2/2022).

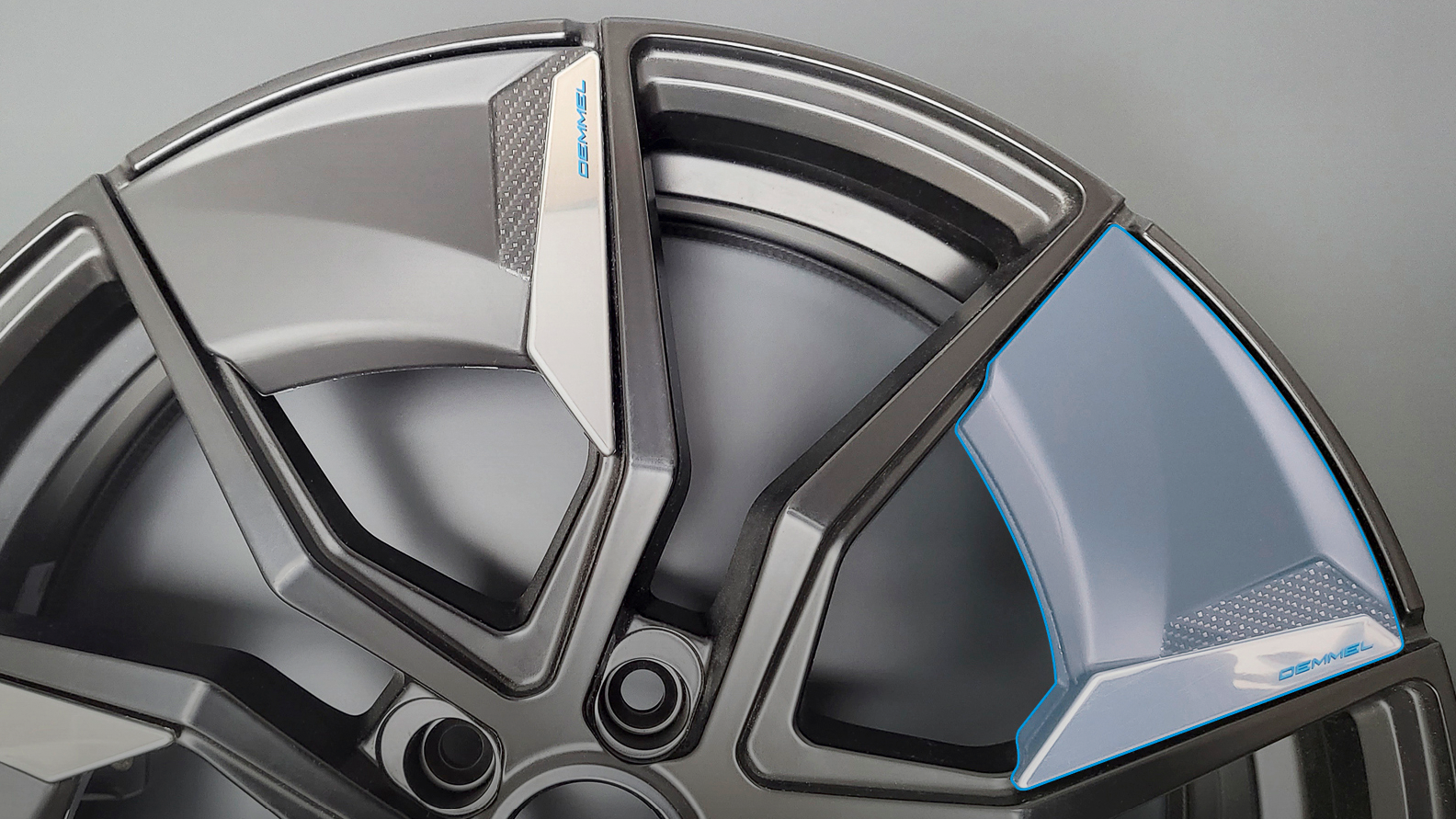

The ingenious and sophisticated alloy design of AMAG AlSi7.REC enables the use of a remarkably broad range of mixed scrap. This development has resulted in exceptional customer benefits for the cast rim: a low carbon footprint combined with high strength and good corrosion resistance. The aero performance wheel inserts offer extra creative scope, including color schemes, and can thus replace the gloss turning procedure that is currently often used.

Starting with rolled high-purity aluminum alloys dedicated to the lightening industry, AMAG has expanded its product portfolio to applications ranging from façades to design elements in the kitchen, loudspeakers, and automotive trims. One of AMAG’s most prominent decorative bright products fulfilling the requirements of an outstanding processability and design flexibility is AMAG AL4 trim 5657 - a high-purity, semi-finished solution, available as coil and sheet. The characteristics exhibited by AMAG’s 5657 is particularly relevant for decorative applications in the automotive sector. Especially middle-class and high-end car manufacturers choose design elements that aim to enhance the appearance of a vehicle and rely on a flawless surface quality as well as complex geometries. The development of novel products, which triggers the introduction of new alloys and altered processing methods, challenges both the part as well as the raw material supplier.

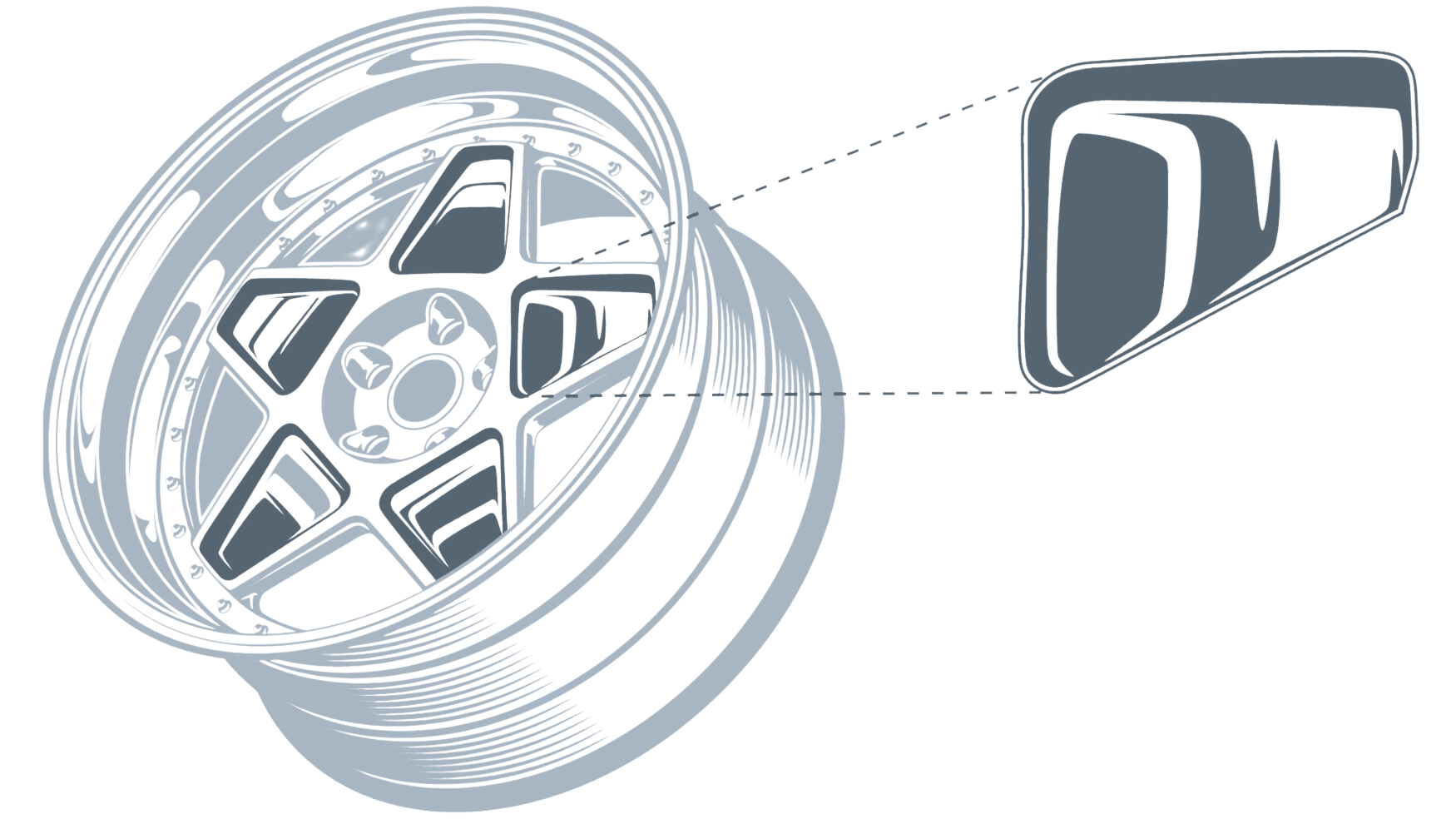

Following the European Standard EN 573-3, the non-heat treatable alloy 5657 in temper H2X exhibits a rather low fraction of alloying elements, entailing mechanical properties that are not only suitable for state-of-the-art forming but also demanding deep drawing processes. Through mechanical and chemical brightening, anodizing, lacquering, screen printing or sand blasting a broad design variety is ensured. Recently AMAG’s 5657 was introduced to automotive rim inserts - functional design elements based on rolled aluminum attached to a car’s rims. These unique design elements do not only attract attention through their appealing appearance and gives a wider design flexibility than bare, state-of-the-art cast rims, on top of that they also offer a functional advantage when it comes to the aerodynamics of a vehicle’s wheel. These easily replaceable attachments to the rim, which are typically smaller than an A5-sized piece of paper, lead to an improved aerodynamic drag of the wheel and in return also in an increase of the vehicle’s range and helps to save fuel or reduce the electric consumption.

The most prominent supplier of these decorative parts to the automotive OEMs is the company Demmel AG - a family business based in Bavaria, Germany, which sources rolled aluminum sheets from AMAG and has a longstanding history in supplying its customers with high-quality, decorative solutions, that involve but are not limited to the automotive business. Starting with decorative interior components made out of wood for predominantly German OEMs, Demmel triggered the introduction of aluminum in this business segment.

Due to Demmels dedication aluminum has become the material of choice for various decorative components in the interior as well as the exterior of today’s vehicles. Following the motto “what has worked once, will work again” with regard to introducing new materials and designs, Demmel keeps coming up with novel solutions making Demmel one of the key players in the European market.

„We have been working together for many years and became pioneers in the decoration business. The technological possibilities of both companies in terms of aluminum are endless. We visit each other and let ourselves be inspired by what we see and hear. Our passion for aluminum is in our genes“, Rolf Tämmerich; CTO of the Demmel AG.