The product names are made up of the following five aspects:

- AMAG branding: AMAG AL4®

- Area of application: ABS automotive body sheet for outer skin applications, BIW body in white for interior structural alloys

- Chemical alloy identification: 6 for 6 xxx aluminum alloy

- Abbreviation to clarify the application reference, eg HD for Heavy Duty for a product that is primarily used in trucks

- The final number describes the typical Rp0.2 yield strength of the material in the delivery condition T4[MPa]

Legend

| ABS | Automotive Body Sheet |

| BIW | Body in White |

| 6IF | Improved Formability |

| 6IH | Improved Hemming |

| 6HD | Heavy Duty |

| 6BKE | Bike |

| 6FO | Forming Optimized |

| 6MS | Medium Strength |

| 6IBR | Improved Bake Response |

| 6ED | Electric Drive |

| 6HS | High Strength |

| 6HF | Highly Formable |

| 6ICP | Improved Crash Performande |

| SPF | Super Plastic Forming |

| UHS | Ultra High Strength |

| H3X-C | Temper H34 Cold Rolled |

| H3X-H | Temper H34 Hot Rolled |

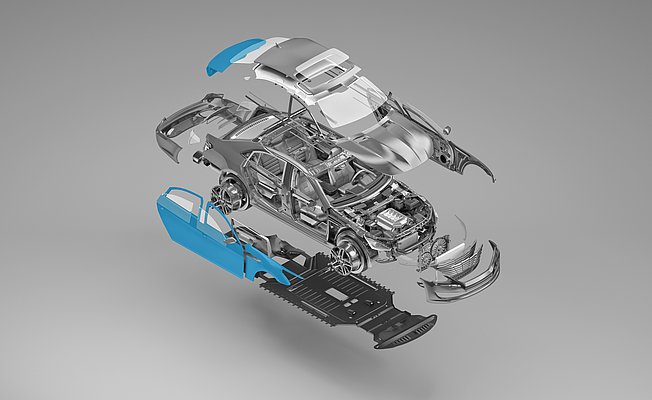

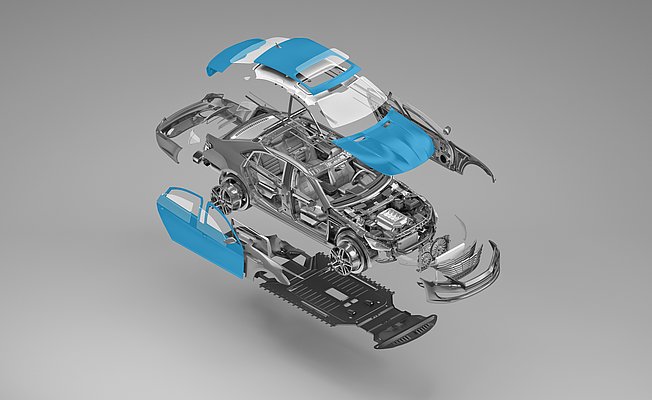

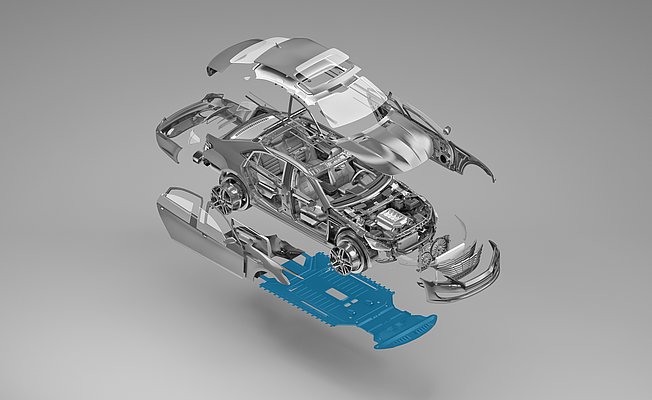

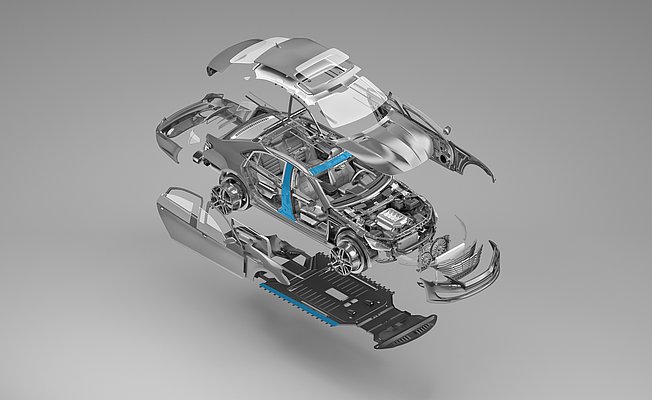

Structure- and outer skin parts, batteries, trim parts

AMAG's product portfolio includes numerous variations of classic alloys that were developed against the background of highly diversified customer specifications. The application profiles range from forming or bending-optimized to strength-optimized, fast-hardening to visible parts or suitable for crashes. Strip widths of up to 2,100 mm can be produced.

AMAG TopForm SPF®

With its TopForm SPF (Super Plastic Forming) materials, AMAG offers a globally unique opportunity to ensure superplastic forming on large-scale industrial plants with consistent quality. Our customers benefit from the production of much more complex geometries or entire assemblies from one sheet.

AMAG TopForm® SPF is also available in widths of more than 2,000 mm and as an AMAG AL4® ever product.

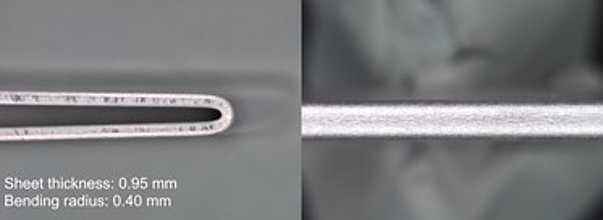

AMAG AL4® ABS 6 IH-100

AMAG AL4® ABS 6IH-100 is optimized for demanding applications in terms of bending and is used for hoods and tailgates. The figure below shows the folded edge of the AMAG AL4® ABS 6IH-100 after one month of natural aging.

- Excellent folding properties combined with good strength

- Good formability

- High surface quality for skin applications

For more information please contact us.

AMAG AL4® ABS 6IF-100

AMAG AL4® ABS 6IF-100 (improved formability) is characterized by its first-class forming properties and excellent surface quality and is therefore ideally suited for use in complex body shell parts. AMAG AL4® ABS 6IF-100 is suitable not only for use as a bonnet or door panel in cars, but also for boot brackets in buses, for example.

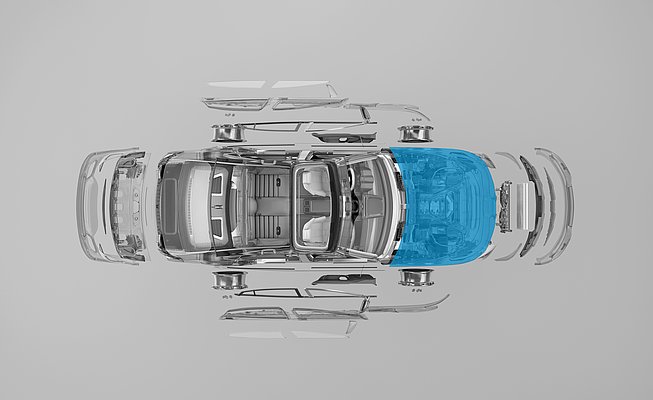

Electromobility

In electric cars, components related to the battery pack in particular are a key factor, because aluminum is not only light and thus helps to achieve longer ranges, but also offers special advantages due to its corrosion resistance. AMAG's specialization in the production of hardened strips with a thickness of more than 3.5 mm is particularly relevant for use in electromobility.

AMAG Al4® BIW 6ED-110

In the area of battery components, there are special requirements for their structural stability. Due to the large load, particularly large sheet thicknesses are required, with the formability being reduced as the sheet thickness increases. AMAG Al4® BIW 6ED-110 brings these opposites together and combines excellent formability with good hardening potential. The comprehensive portfolio of mechanical properties is also combined with a high proportion of recyclate and thereby creates the ideal conditions for sustainable use in electromobility.

AMAG Al4® BIW 6ED-110 is also available as AMAG AL4® ever product.

- Ideal for battery applications

- Improved strength to formability ratio

- Low carbon footprint (part of the AMAG AL4 ever family)

For more informations please contact us.

AMAG Al4® BIW 6 ICP

AMAG AL4® BIW 6ICP is a high-strength alloy with increased deformation capacity and therefore optimized crash safety, specially developed for use in structural components. Premium e-car manufacturers use AMAG AL4® BIW 6ICP (Improved Crash Performance) as battery protection. Excellent forming properties in the solution-annealed T4 condition are complemented by high energy absorption potential in the age-hardened T6 condition. In addition, the product is ideally suited for use in the hot-forming process. The material is heated from the initial state F to the solution annealing temperature, deformed, quenched in the tool and then artificially aged. The result: Complex component geometries with high strength.

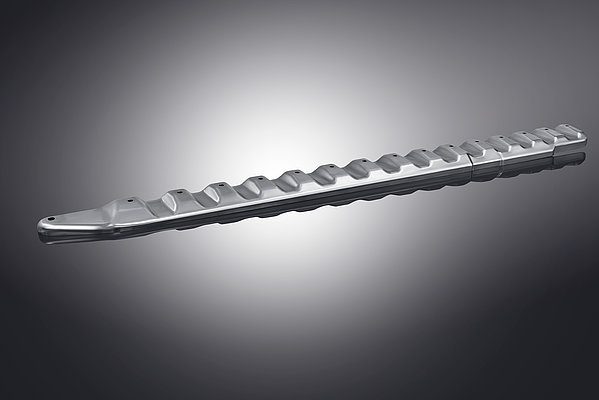

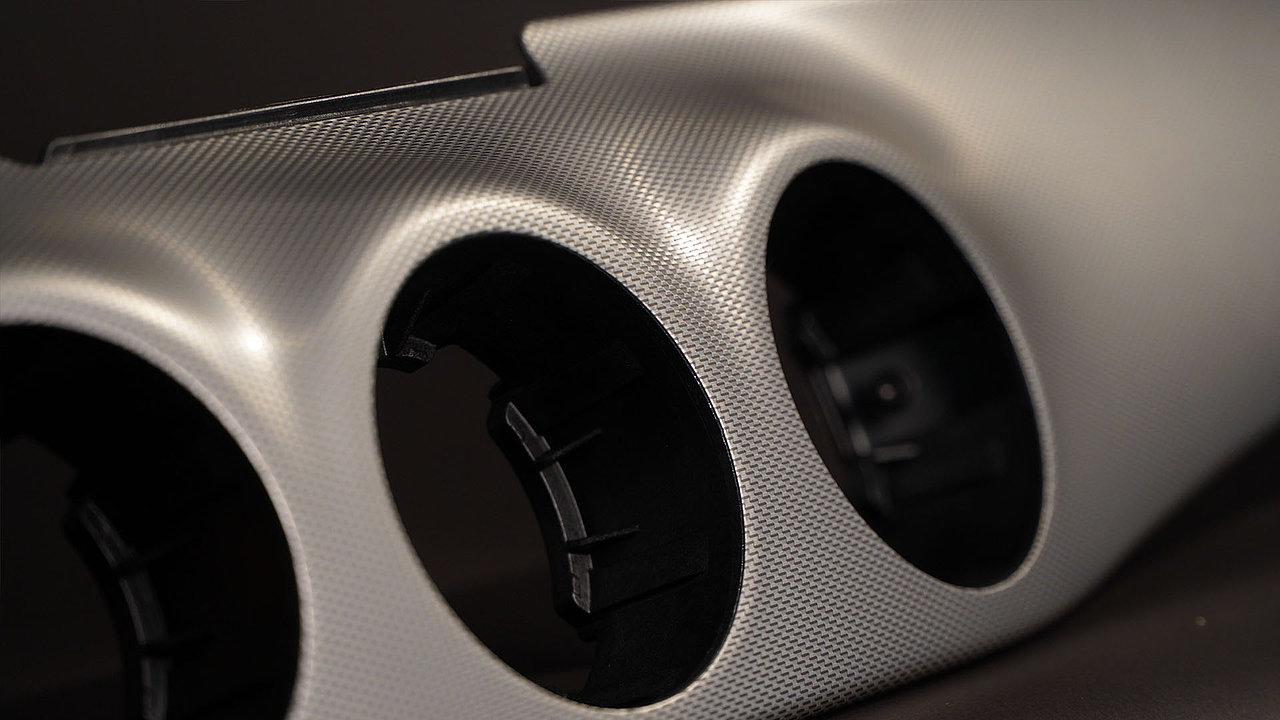

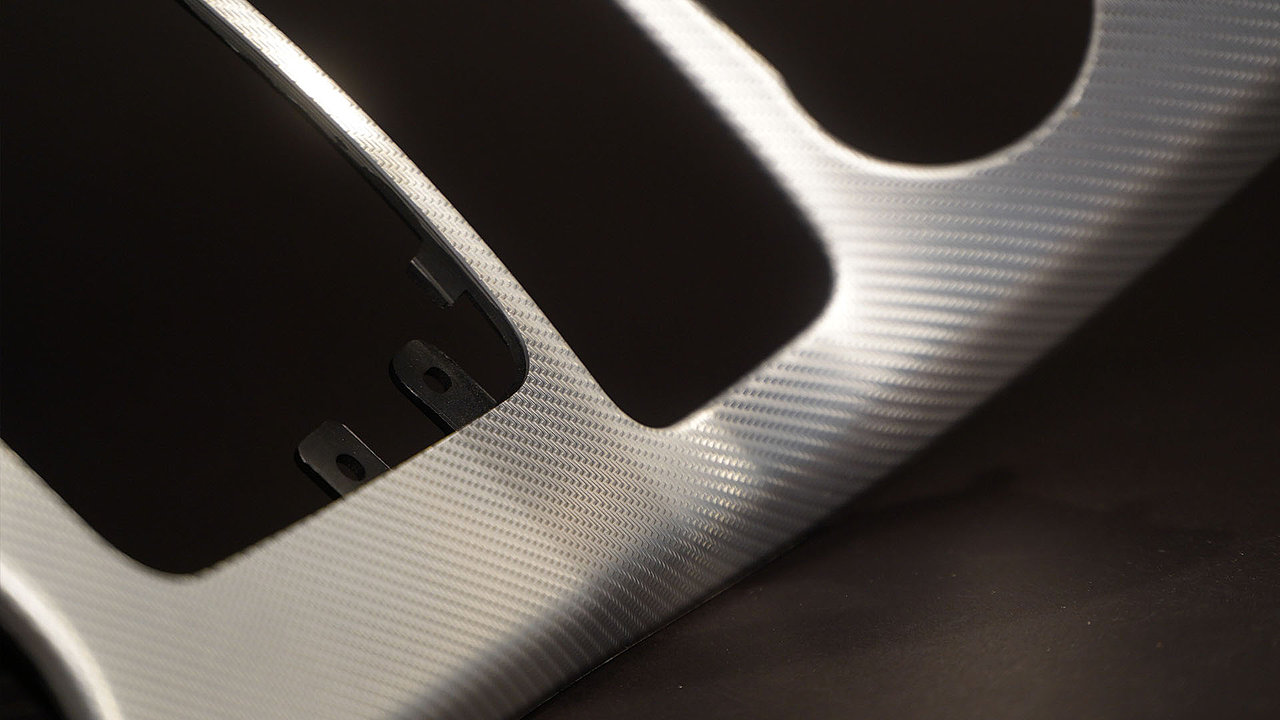

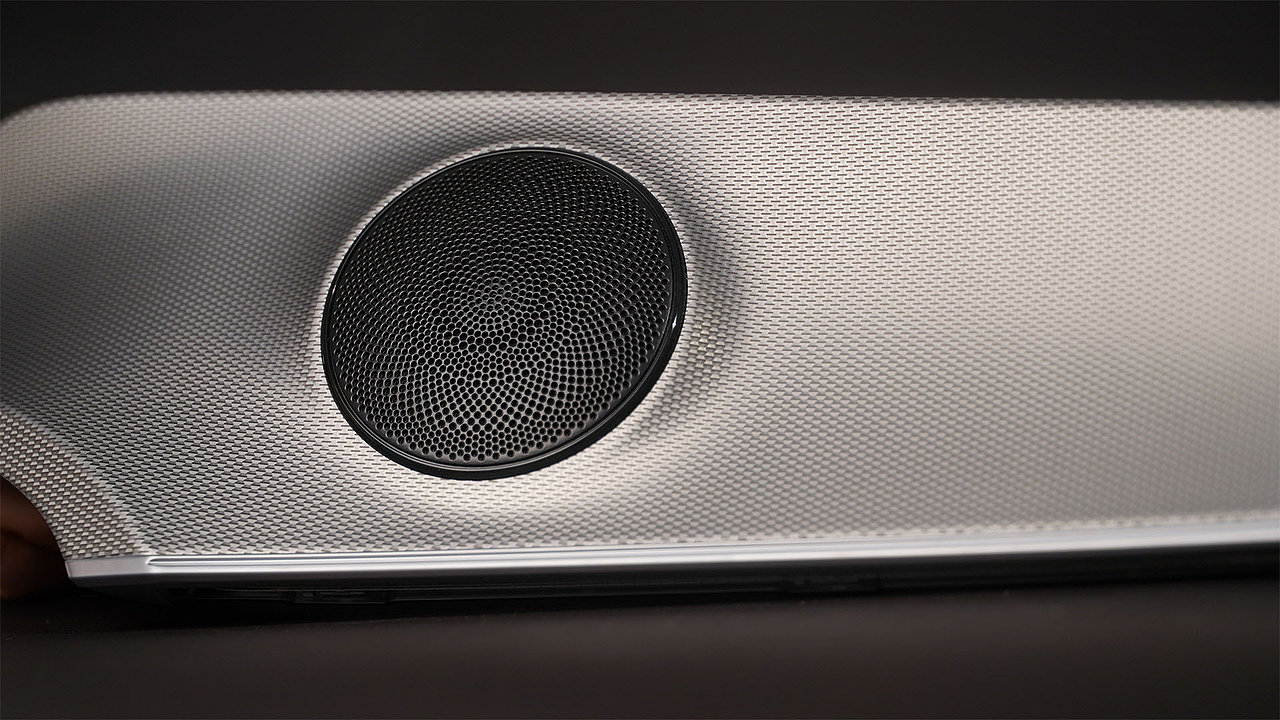

Trim parts

In addition to being used in outer skin and structural components, aluminium is also an important design element in vehicle construction. In order to realize an emotional design experience, trim parts in particular play a central role. For this demanding application, both indoors and outdoors, AMAG combines its many years of know-how in the production of high-quality surfaces with the best formability. AMAG's trim part portfolio includes painting qualities as well as anodizing and gloss qualities.

The following products, for example, are used as high-gloss materials for automotive trim parts:

- 8014 H21 LQ Bright finish

- 5657 H22/24/26 LQ/AQ Bright Mill Finish

- 5005O LQ Bright finish

- 5505 H22-24 Bright Mill Finish