MODERNIZATION OF THE FOUR-HIGH COLD ROLLING STAND

AMAG rolling is a specialist in the manufacture of cold-rolled products. Our extensive product portfolio ranges from sheets for the aviation and automotive industries to special applications such as brazing materials and consumer electronics to bright products and prerolled aluminium bands.

While the modernized cold rolling mill has provided excellent service over the years, its electrical, automation and safety technologies had become outdated. Modernizing the system was the next logical step in guaranteeing outstanding supply performance for our customers. In PRIMETALS, we have a partner who has already successfully implemented several modernization projects at our Ranshofen site.

In detail, the modernization project concerned the existing gauge and evenness control systems, replacing technological measuring instruments, implementing level 2 process automation, updating the electrical and automation technology including the sensors and cabling, and replacing various auxiliary systems. As with all investments and modernization projects undertaken by AMAG, we also considered the latest occupational safety standards.

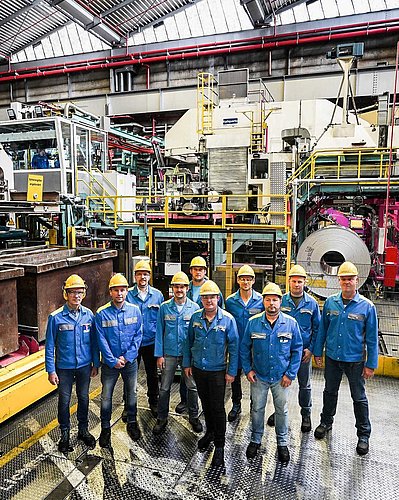

Despite this lengthy list and the considerable challenges involved, we were still able to implement the entire modernization on schedule and on budget all while reducing production downtime to a minimum. To put the scale of the challenge into context, the cabling to be replaced alone would stretch from Ranshofen to Hohensalzburg Fortress (approx. 62 km/38.5 miles). At peak times, there were 150 fitters, commissioning engineers from PRIMETALS and AMAG rolling employees present on the building site. AMAG therefore developed and successfully implemented its own coronavirus safety concept in the preliminary stages of the project.

In addition, we went to great lengths in production planning to ensure we were able to meet all production deadlines despite the unbroken four-week downtime in August 2021. This ensured that customer supplies were never compromised. We brought some orders forward and moved others to Cold Rolling Mill 2. The fact that AMAG rolling is largely able to fall back on redundant production routes with two hot and cold rolling mills at a single location was a decisive advantage.

Customer benefits

| Product quality | Supply security |

|---|---|

In respect of product quality, the new gauge and evenness control system and the new process automation have further improved results in terms of evenness, avoidance of edge cracks and general product consistency. Further optimizations and productivity increases can be expected in the future.

| Thanks to the modernization of the four-high cold rolling stand, two state-of-the-art cold rolling mills are once again in use at AMAG. This redundancy ensures our customers' supply security at all times.

|

Would you like to know more?