NOT ALL THAT GLITTERS IS GOLD. IT CAN ALSO BE ALUMINIUM.

AMAG regards itself as a premium manufacturer of rolled aluminium products with a high proportion of bespoke products.

Very often, these are products with special strength or forming properties. However, surface quality also plays an important role in almost all products, and not only in the case of those sheets that are manufactured specifically for decorative applications. All AMAG products can be tested for manufacturability as CO2-optimized AL4®ever or ASI variants. AMAG is also a specialist for particularly fastidious surfaces. The surface properties determine not only the visual appearance of a sheet, but also formability, solderability, slip resistance, bondability and much more. A closer look is therefore worthwhile. For this reason, AMAG created a "Wall of Sheets" at the Düsseldorf Aluminium Trade Fair, which was used to inform visitors to the AMAG trade fair stand about the special features of the individual sheet surfaces. The following is an excerpt of this presentation.

AMAG AL4® AP5 BRUSH+

Areas of application: Facades and architectural applications for exterior and interior use AMAG AL4® AP5 Brush+ is part of the AMAG AP (Architectural Products) series and is characterised by its coarsely structured texture and coarsely brushed surface with a uniformly diffuse reflection. The decorative surface is a lightweight alternative to brushed steel façades. Due to its good anodising properties AMAG AL4® AP5 Brush+ is also extremely resistant to weathering and corrosion.

Customer benefits: Best weathering resistance, very good processability, uniform surface finish.

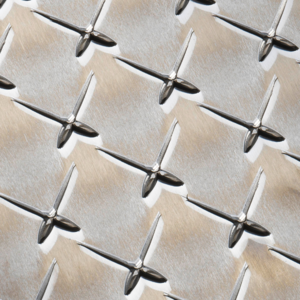

AMAG TOPGRIP®

Areas of application: In any area where non-slip prevention must be ensured, such AMAG TOPGRIP® as in cable car construction or on platforms and stairs, wind turbines or cranes. Can be used both indoors and outdoors and also available as a decorative version.

Characteristic of AMAG TopGrip® is the asymmetric criss-cross tread structure. This patented tread design offers superior non-slip properties (R11) and significant weight advantages while maintaining an impressively low CO2 footprint. In addition to the unique AMAG TopGrip® treadplate pattern, AMAG also offers four other treadplate designs.

Customer benefits: excellent slip preventation, decorative

AMAG PROCATH®

Areas of application: Cathode sheets for zinc electrolysis

AMAG PROCATH® is characterised not only by optimum conductivity, but above all by excellent flatness. As a result, minimal spacing between the cathodes and anodes in the electrolyte bath can be realised. In addition to optimised space utilisation, this also enables highly efficient use of resources.

Customer benefits: Excellent flatness, excellent forming tolerances, unique edge trims for long product life

AMAG AL4® FOIL 1HQF

Areas of application: Aluminium packaging of all kinds for food, pharmaceuticals, labels or technical applications

In order to be able to produce high-quality aluminium foil, a high-quality primary material is required. AMAG ensures this material quality through the use of special alloys, as well as through sophisticated process management. The result are products with outstanding mechanical properties.

Customer benefits: Increase in productivity through the use of wide foil prerolled coils, products with premium quality in terms of holes/pores, products available as ASI certified material, Closed-loop recycling

AMAG AL4® ABS 6IF-100

Areas of application: Body outer skin parts such as doors, boot lids, bonnets, roof

Car body outer shell parts need aluminium sheets with high formability and folding potential, as well as sheets with particularly good surface quality. To ensure this, AMAG AL4® ABS 6IF-100 is cast with a narrow alloy tolerance during the rolling ingot production and produced in the rolling mill using a quality-optimised process chain. The acronym IF in the product name stands for improved formability.

Customer benefits: Very good formability for high design demands, excellent surface quality for first-class painting results, high final strength in a hardened state

AMAG AL4® TRIM 5657

Areas of application: Trim parts for vehicles

In view of the relatively similar technical standards, vehicle design is one of the most important differentiating criteria of car brands today. In order to realise an emotional design experience, trim parts in particular play a central role. For this demanding exterior and interior application, AMAG combines its many years of know-how in the production of high-quality surfaces with the best formability.

Customer benefits: wide variety of designs, easy to exchange or replace

AMAG AL4® FuelTanks 5754

Areas of application: Fuel tanks for commercial vehicles AMAG Al4®

FuelTanks 5754 is optimally suited for use as a shell circuit board in fuel tanks of transport vehicles. In terms of processability, AMAG Al4® FuelTanks 5754 offers the ideal balance between mechanical strength (stiffness of the material) and elongation at break (formability, e.g. bending). In addition, this material is easy to weld and very corrosion resistant.

Customer benefits: Tightest shape tolerances, uniform surface structure and -colouring, uniform microstructure and lowest and uniform residual stresses

AMAG TOPCLAD®

Areas of application: Solder clad materials for heat exchangers in industrial applications and in the automotive/transport sector, especially also for battery cooling in electric vehicles

AMAG is the specialist for plated materials: whether for corrosion protection, for high-gloss surfaces or for cladding with solder materials for ideal solderability, AMAG is in a position to individually fulfil a wide range of customer requirements.

Customer benefits: Good formability, thermal conductivity, low weight, comprehensive material combinations, cladding layer thicknesses from 1.5 to 20.0 percent with tight