Responsible value chain

Appreciating value creation - that's what we do.

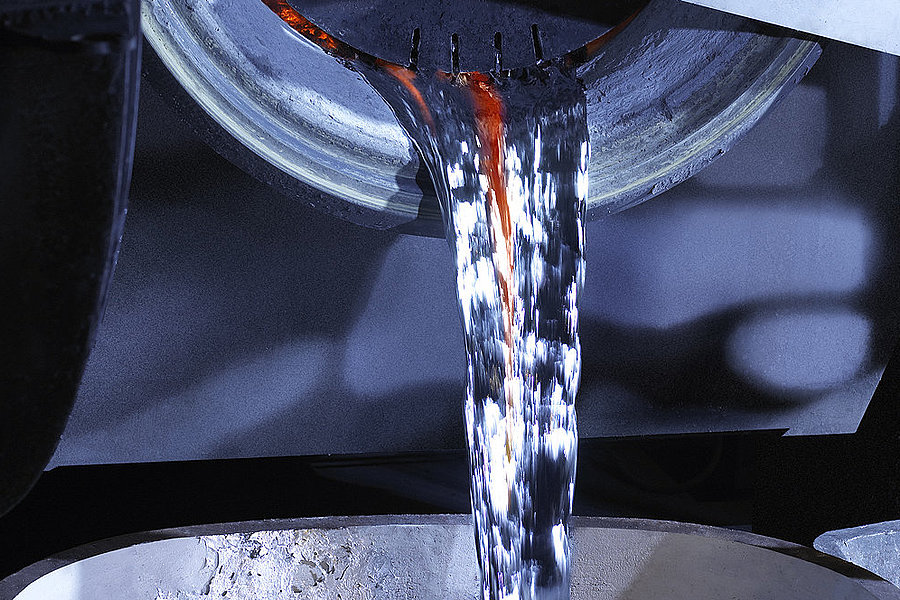

Recycling

Aluminium 4 ever and ever and ever and ever and ever…

The recycling of aluminium has increased sharply worldwide in recent years, due on the one hand to the greater quantity of secondary materials available and on the other hand to the ecological and economic advantages compared with primary production. By recycling aluminium, up to 95% of the energy can be saved compared to primary aluminium production - therefore making a significant contribution to the reduction of emissions.

Aluminium recycling offers the possibility of closing material cycles within industrial production processes. For this reason alone, it is in the very own interest of the aluminium industry to use existing scrap. At the end of utilization of aluminium products - be it from construction, transport, or packaging - it is therefore important to keep these products in the material cycle.

AMAG has established a separate category for products with a high recycled content and low carbon footprint:

the AL4®ever series. Find out here about the environmentally friendly AL4®ever product line.

Raw materials

Sustainable sourcing

The responsible use of raw materials along the value chain is an integral part of corporate policy. The most efficient and responsible use of resources, recycling and the closed-loop concept are anchored in the corporate strategy.

AMAG is a founding member of the Aluminium Stewardship Initiative (ASI), which was launched in 2012. It is an association of various stakeholders in the aluminium industry with the aim of making the production of aluminium as sustainable as possible. To this end, an independent, objective certification system was developed that considers all steps - from raw material mining, through production and use, to the recycling of aluminium.

AMAG is already certified to both standards issued by the initiative - ASI Performance and Chain of Custody (CoC) standard - because of its responsible aluminium production and processing. To achieve the ASI Performance Standard, sustainable production and processing of aluminium must be demonstrated for the relevant site. Sustainability here is based on various ecological, economic, and social criteria.

The ASI-CoC standard goes one step further and starts already outside the company's own factory gates by stipulating compliance with the same strict standards and criteria for input material suppliers. This covers all steps of the value chain - from production of bauxite as well as secondary aluminium, through processing, to the finished product.

To achieve and maintain certification, audits are conducted by external authorized auditors.

![[Translate to English:] Weltkarte](/fileadmin/user_upload/weltkarte.png)

Dipl. -Ing. Dr, Marlis Zöhrer

Head of Sustainability Management

Tel.: +43 7722 801 3548